Hay drying in barns towards sustainable agriculture

France

Introduction

Jean-Noël Landemaine took over his parents’ farm in 2003, which was run on 100 hectares of conventional land. The farm produced 15 hectares of cereals, 25 hectares of silage maize and 425,000 litres of milk. Jean-Noël quickly became aware of climate change and the decline in biodiversity; he could no longer continue to farm as his parents had done.

This questioning of the sustainability of his business prompted Jean-Noël to change his system to all-grass, and prompted him to think about his production methods as a whole, leading him to set up barn drying of hay. This method involves drying fodder at an early stage and over a short period. Harvested in this way, while still damp, the hay retains all its nutrients.

The dryer recovers warm air from under the roof; the heat is recovered by a fan and blown onto the pile of hay stored in bulk in the building. According to Jean-Noël Landemaine, “It was the best way out of everything I could no longer accept.

Presentation of the project

When Jean-Noël Landemaine took over his parents’ farm with his wife at Louverné in Chantrigné, a commune in the north of the Mayenne department, he was determined to break with the system handed down by his parents and relayed in training centres. The post-war system of silage maize for animal feed was called into question and disappeared, to be replaced by an all-grass system.

His sensitivity to the environment and the growing expectations of consumers for products from more sustainable agriculture are his main motivations for moving towards more sustainable farming, despite the fear of change.

As part of the transition to more sustainable farming, conventional barn drying of hay is the first step in demonstrating a sustainable system for the next generation. It shows that it is possible to improve the quality of work and protect the environment while maintaining the farm’s economic profitability. It is a springboard for conversion to organic farming, which will help to improve :

– water quality, by limiting leaching and reducing the use of plant protection products

– the farm’s carbon footprint, by reducing fuel consumption and plastic waste, and eliminating the need to import soya by boat. The hay retains its nutrients better with this new method, keeping the heifers in better health and, as a bonus, reducing veterinary costs. Farmers are also more independent when it comes to feeding their animals properly.

The first stage of the project involved planting grassland and then reducing the proportion of silage maize in favour of wraps. Work on the construction of the 1,000m² dryer and the installation of the forage claw will then get under way in 2019, with drying operations due to begin in 2020. The project also incorporates a dehumidifier to remove the air before passing it through the fan, thereby sending dry air under the hay, even in rainy weather. The water evaporated by the plant will be recovered to give the animals something to drink. This overhaul of the system is also accompanied by a programme to replant hedges on the farm. All these reorganisations are leading him to obtain organic farming certification in 2020. And Jean-Noël Landemaine didn’t stop there. Noting the reduction in his farm’s carbon footprint, he took his thinking as far as the carbon market and set up an association with the aim of remunerating farmers for their virtuous practices and financing the ecological transition. His current aim is to pass on his experience to young people in training centres, to help bring about change.

The overall investment in the dryer was very substantial for the farm, so Jean-Noël Landemaine went knocking on the doors of the banks. To reassure the investors and limit the bank loan, he asked the GAL Haute Mayenne to help him put together the LEADER grant application. In this case, European financial support was a real lever in bringing the project to fruition.

The emblematic character of the project

The project is fully in line with the strategy of the Haute Mayenne LAG, which aims to develop economically viable agriculture while contributing to major environmental issues. With this project, the Landemaine couple’s challenge has been to combine the economic equilibrium of the farm with a shift towards more sustainable agriculture.

Drying is a technique that is used in mountain areas by all the cheese AOCs (importance of hay for cheese-makers). Switzerland and Austria were pioneers in this technique, and the result is a certain quality of life: meadows rather than cultivated fields, no pesticides, etc.

The technique of drying in barns is still not widely used in Mayenne, particularly in northern Mayenne. The dehumidifier integrated into the dryer presented here is the most advanced version of this technique.

Around 85% of systems with dryers are installed on farms that are certified organic, so it is a special feature of this project that it was initially installed on a conventional system.

As Jean-Noël Landemaine has shown, the project to dry hay in barns can be transposed to all farms and adapted to all regions. Deploying this system is one of the farmer’s objectives.

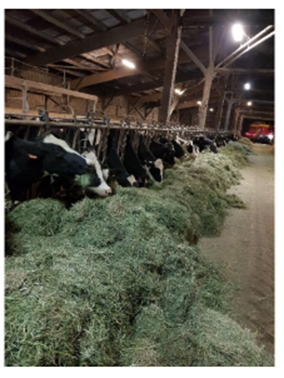

Pictures

GAEC de Louverné, Jean-Noël Landemaine et Marion Gardrat

Haute Mayenne

Pays de La Loire